ANDRITZ Gouda, Seaweed to Market at Scale: Integrated dewatering, extraction, evaporation, and dryin

2026-02-05

ANDRITZ Gouda BV, part of the ANDRITZ Group, is a versatile manufacturer and supplier of processing equipment for the food, chemical, mining & mineral and environmental industry. The comprehensive product portfolio covers everything from standalone equipment to complete process solutions.

The company combines more than 100 years of technological expertise with the ability to manage all stages of large industrial projects. Together with state-of-the-art manufacturing technologies, ANDRITZ offers an integrated approach for the set-up of processing lines. “We have experience in designing and building plants, including engineering, installation, start-up, service, and commissioning of the plant.”, Says Diko Kalkdijk, area sales manager at Andritz.

The international technology group ANDRITZ provides plants, equipment, services, and digital solutions for a wide range of industries, including pulp and paper, metals, hydropower, environment and energy, and many others.

Creating growth that matters

As a global leader in technology and innovation, ANDRITZ is committed to fostering progress that benefits customers, partners, employees, society, and the environment. The company’s growth is driven by sustainable solutions enabling the green transition, advanced digitalization for highest industrial performance, and comprehensive services that maximize the value of customers’ plants over their entire life cycle.

From separation technologies to finished product

With its expertise in process design, the company, among others, specialises in drying, separating and concentrating raw materials to turn complex raw material into usable and valuable products. This includes technologies for extraction, evaporation and a wide range of drying solutions, such as paddle, drum, helix, plate and spray dryers.

Clients are supported by designing and delivering complete process lines, including everything from pre‑treatment and cooking to hydrolysis, separation, concentration, and drying of the final product.

This integrated approach is particularly relevant for industries where raw materials are complex and variable. Seaweed is a clear example of this.

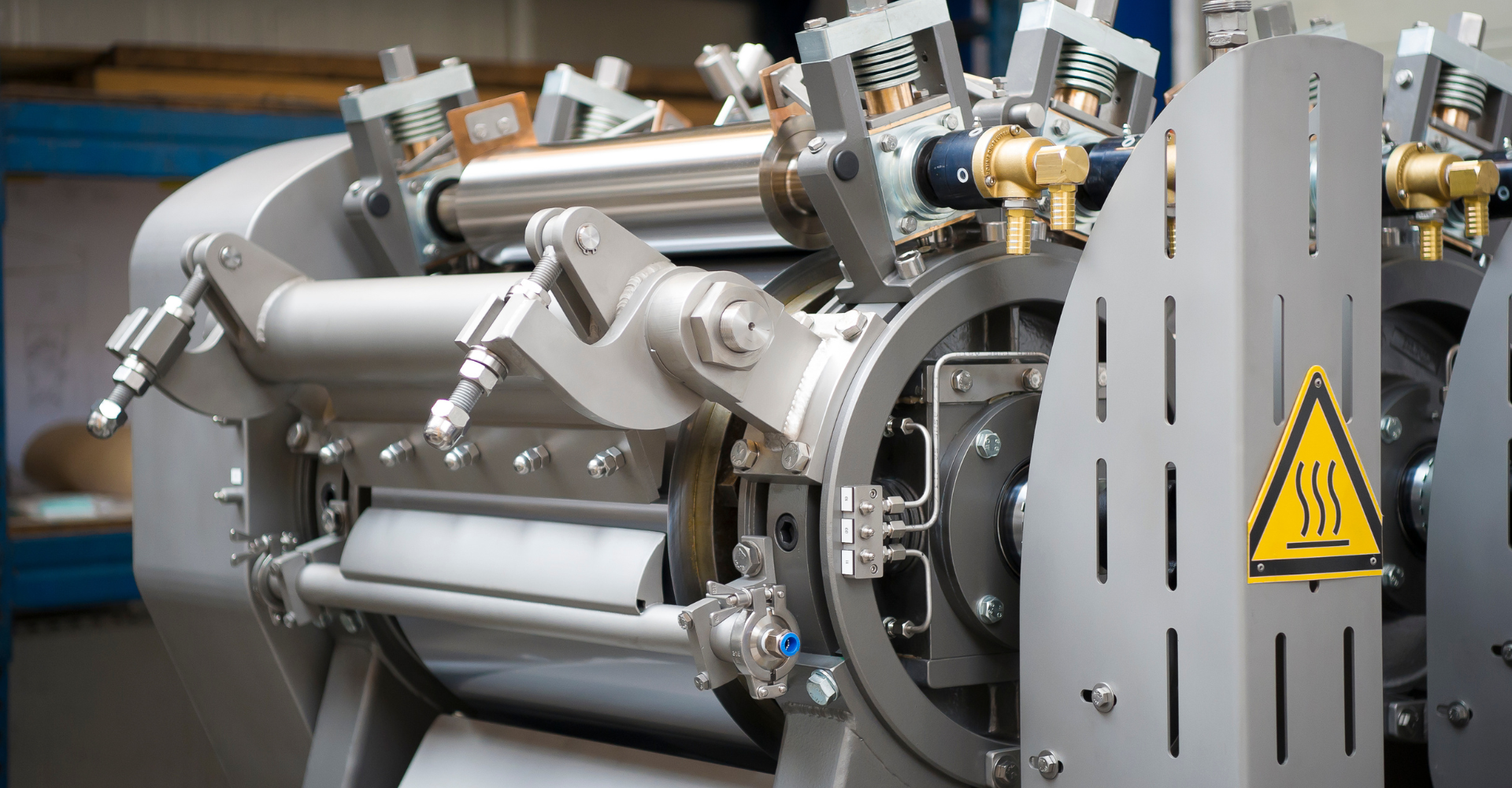

A double drum dryer from Andritz Gouda B.V.

Food Innovation Xperience center (FIX) in Waddinxveen

To ensure the most effective transition from pilot plant to industrial scale, ANDRITZ believes in working together with customers. The Food Innovation Xperience center (FIX) in Waddinxveen is not just a facility – it is a collaborative environment where customer teams and ANDRITZ experts join forces.

The Food Xperience Center in Waddinxveen

Together with its customers, processes are tested, optimized, and refined, leveraging both the ANDRITZ extensive technology portfolio and the customer’s unique product knowledge to co-create solutions that are ready for industrial implementation.

The high-end, food-grade and ATEX pilot facility is designed for joint experimentation. By combining the customer’s insights into raw material behavior with ANDRITZ’s process engineering expertise, we collaboratively identify and address scale-up challenges. This partnership ensures that every process step – from dewatering and extraction to drying – is validated and optimized before full-scale production

For emerging value chains such as seaweed, this kind of pilot scale testing is essential.

The Food Xperience Center in Waddinxveen

A role in the developing seaweed industry

While seaweed processing is still a relatively young field compared to more established biomass streams, the company sees clear parallels with industries it already serves. According to the company, many of the challenges in seaweed processing relate to handling variability in the raw material and designing robust pre-treatment and separation steps.

ANDRITZ experts are ready to play a role particularly in the phase where harvested seaweed is processed into multiple components. This includes separating fractions, concentrating valuable compounds and producing stable end products through drying.

The company emphasises that pre-treatment is critical. How seaweed is handled directly after harvest strongly influences downstream processing efficiency and product quality. Designing the right process from the start is therefore essential.

Looking ahead and collaborating within the network

As the European seaweed sector continues to professionalize, the company is committed to building strong, collaborative relationships across the value chain. The aim is to accelerate the transition from pilot projects to commercially viable operations – ensuring that every solution benefits from the combined strengths of all partners involved, by joining forces with customers, technology developers, and innovators,

By joining the European Seaweed Association network, ANDRITZ Gouda aims to deepen its understanding of the specific needs of the seaweed sector and connect with partners across the value chain. The company believes that close collaboration between growers, processors, technology providers and end users will be crucial to move from pilot projects to commercially viable operations.

The company knows that the journey from pilot plant to industrial production is most successful when it’s a true partnership. By combining ANDRITZ proven technologies with the customer’s product vision and expertise, robust, scalable, and ready for future solutions will be delivered.

Want to know more? Contact ANDRITZ Gouda B.V.by phone +31 182 623 723 or email sales.gouda@andritz.com