Kelpi: turning seaweed into high performance packaging

2025-12-18

A mission to remove plastic from packaging

Kelpi is a UK based materials innovation company that wants to take the plastic out of packaging. Founded in 2020, the company uses seaweed to create biobased coatings that can replace single use plastics in demanding applications. It grew out of a collaboration between serial entrepreneurs Neil Morris and Murray Kenneth and Professor Chris Chuck of the University of Bath, who shared a concern about microplastics and plastic pollution on land and at sea. Their ambition is simple and bold. To remove plastic packaging from the environment by giving brand owners a better option they can use at scale.

Today Kelpio has a team of around eighteen people and is led by chief executive officer Hugo Adams. He joined the company as chief commercial officer and became CEO in early 2025. Before Kelpi he worked in senior roles at companies such as The Body Shop, Kraft Foods, Dyson and Marks and Spencer, where sustainability and consumer products came together in practice. A long-standing interest in the ocean made Kelpi a logical next step. The company is also a certified B Corp, underlining its commitment to combining profit with positive impact.

What Kelpi makes: a high barrier seaweed-based coating

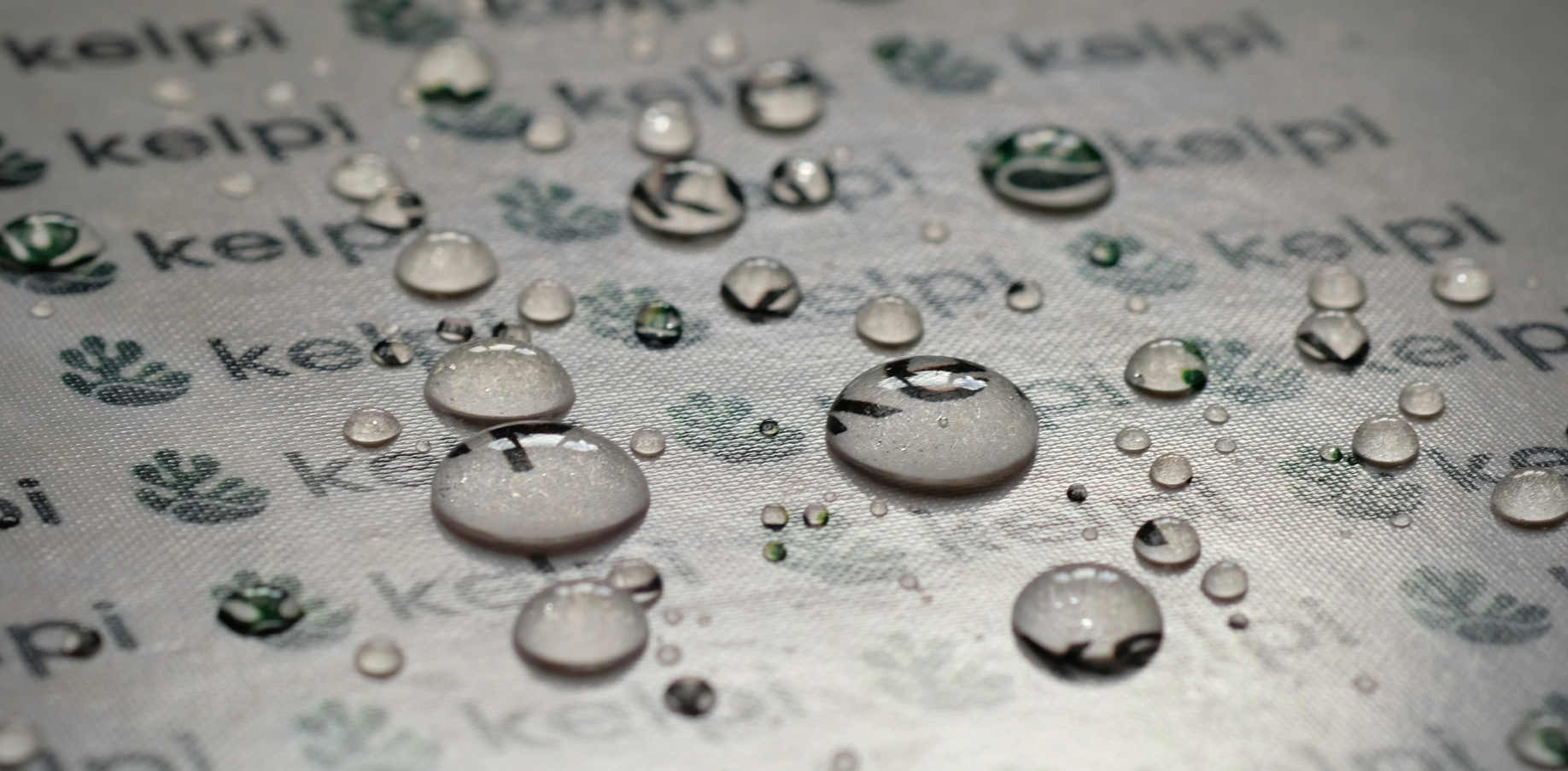

Kelpi does not make finished packaging. Instead, it sells a high barrier coating that turns paper, card and fibre into premium performance packs. From seaweed polysaccharides and vegetable oils the team creates a thin layer that provides a strong barrier to water, moisture and oxygen as well as resistance to grease and acidic contents. This allows products to reach the shelf life that brand owners expect in food, drink, personal care and home care, while keeping fossil plastic out of the pack. In independent evaluations, Kelpi’s material has always exceeded the performance of competing solutions and matched or exceeded the performance of incumbent fossil fuel plastics.

How customers use it: powder, pellets and full drop in compatibility

For many in our seaweed-based network the way Kelpi supplies its material is particularly interesting. After synthesis the coating can be delivered either as a fine white powder or as pellets. The powder is dispersed into a liquid and applied on conventional paper coating lines. The pellets can be run on standard plastic extrusion machinery and applied as a layer on paper or card. The material has been designed as a true drop in solution for existing industrial lines, so converters can work with it without major new investment. Kelpi itself does not farm seaweed or run coating plants. It buys processed feedstock from biorefineries, uses contract manufacturers for synthesis and works with large packaging companies for conversion, positioning itself as a research and development hub in the middle of the value chain.

Why seaweed: a renewable feedstock with real performance

Seaweed is the main feedstock in Kelpi’s technology today. The company currently uses agar from red seaweed species sourced from warmer waters such as India, Vietnam and Indonesia, because this delivers the high-water barrier needed for its first products. In parallel the team is exploring other feedstocks including different seaweed species, agricultural side streams and cellulose. The clever step in the technology is the way seaweed polysaccharides are combined with vegetable oils to create the required function. Seaweed grows quickly, absorbs carbon dioxide and does not need land, fertiliser or fresh water, which makes it a promising basis for low carbon materials.

Recyclable and biodegradable end of life

At the end of life, paper and card coated with Kelpi’s material can enter existing paper recycling streams. If a pack escapes collection, the coating will biodegrade in the natural environment as microorganisms break down the bond between the seaweed component and the vegetable oil. The result is a material that behaves like plastic in use but does not leave plastic behind in the form of persistent microplastics.

Scaling up: from lab samples to industrial trials

In the past year Kelpi has moved from laboratory work towards industrial reality. The team has scaled from gram batches to half tonne quantities, coated kilometres of paper instead of single sheets and produced hundreds of sachets rather than handmade samples. Kelpi prepares for its first commercial launch in the home care sector, starting with sachets for detergents and cleaning liquids. Food contact approval is in progress with regulators in North America and Europe and will open the door to applications in food and drink once granted.

A collaborative mindset for a growing industry

Kelpi joined the European Seaweed Association to be part of the wider seaweed community and to help grow markets for seaweed-based materials. The team is clear that the challenge of replacing plastic is too big for any single company and that collaboration is essential. They are open to working with seaweed farmers, biorefineries, converters and brand owners who want to explore new applications for seaweed in packaging. Members can approach Kelpi for joint development of coatings, for paper and card-based packaging concepts and for partnerships that help remove plastic from some of the most demanding product categories.