Building the ‘Starbucks’ of the Seaweed Industry

2025-08-25

Seaweedland – Farming seaweed on land with a franchise model

Meet Sven Rusticus, founder of Seaweedland and a new member of the North Sea Farmers community. In just three years, he has grown the company from an idea into an operational pilot plant that already supplies 2,000 kilograms of seaweed per year to Michelin star restaurants such as De Librije. And this is only the beginning.

How it all started

Sven’s first encounter with seaweed came three years ago at the Seagriculture conference. With a background in process & control engineering, he knew that scalable, efficient food production thrives in controlled conditions.

“We don’t pick tomatoes from the wild anymore, so why would we do that with seaweed?”

The idea was born: grow seaweed on land, in greenhouses, using circular systems, to avoid challenges of the ocean and deliver a clean, safe and reliable product.

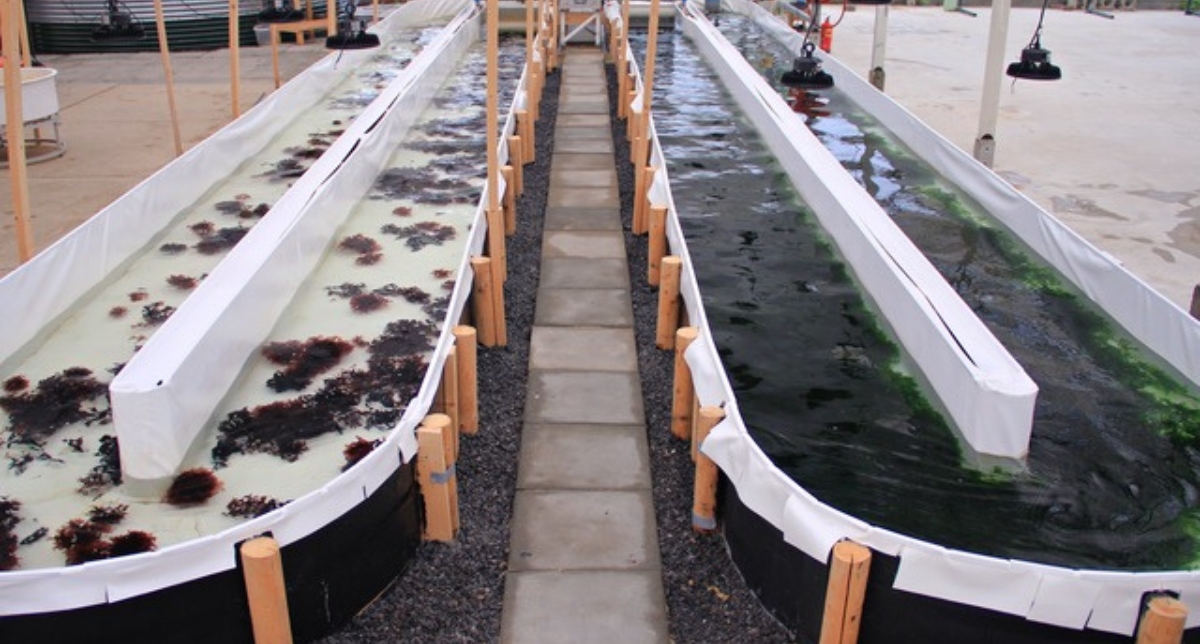

The hatchery of Seaweedland

Circular sites in the Netherlands

Today, Seaweedland operates a pilot facility in Heerhugowaard, next to Hortimare, the renowned seaweed breeding company. Meanwhile Seaweedland is developing production locations at multiple locations:

- Magnesium salt mine in Groningen, cultivating seaweed in residual salt water streams, using excess heat and CO₂.

- Greenhouses in Friesland, growing seaweed in repurposed greenhouses, abandoned due to high energy costs and saline groundwater.

The result: circular production systems that not only supply seaweed but also help valorise residual streams.

From 2,000 to 200,000 kilos

Palmaria palmata grown by Seaweedland

Seaweedland currently produces three seaweed species for the human food markets: Ulva, Palmaria palmata and Gracilaria. De Librije in Zwolle is a loyal customer, while more restaurants and chefs are finding their way to Seaweedland.

The potential goes further: Market commitments are in place for 90,000 kilograms and the company is planning a 200,000 kilograms production site. “The demand is there; now it’s up to us to scale up.”

Seaweedland is also working on the cultivation of Asparagopsis seaweed, well known for its capacity to reduce methane emissions from cows. Dutch farmers and major companies in the feed and dairy industry are involved.

Scaling Through Franchising

The pilot plant of Seaweedland

What sets Seaweedland apart is its franchise concept. The company has built a complete, replicable pilot plant, including infrastructure, measurement & control systems that entrepreneurs worldwide can adopt. “We want to enable others to start their own seaweed business faster, using our proven technology and expertise.”

With international interest from the US, India, Japan, Spain and Mauritius, the network is growing quickly.

Products made with seaweed from Seaweedland

Sustainable Happy Meals

Sven thinks big and outside the box: a sustainable Happy Meal at McDonald’s, comprising:

- A hybrid burger with 40% meat, 60% plant-based, half of it seaweed.

- Meat from cows fed with methane-reducing Asparagopsis seaweed.

- Chips seasoned with seaweed instead of table salt.

- Packaging made from seaweed-based film.

“It may sound utopian”, Sven admits, “but in Singapore you can already choose chips with seaweed salt. Why not here?”

Ulva, Sea lettuce, grown by Seaweedland

What is Seaweedland looking for in the NSF network?

For Sven, the annual North Sea Farmers conference is the place to meet customers. A conversation in Scheveningen last year led to a collaboration with Verstegen. “The more market parties and customers at the conference, the better. That’s where it starts.”

He also wants to bring inspiration and optimism. “It’s not always easy in the seaweed industry. We show that it can be done by collaboration, knowledge-sharing and perseverance.”

👉 Interested in collaborating with Seaweedland? Get in touch with @Sven and his team or meet them at North Sea Seaweed 2025.

The team of Seaweedland